THE PROJECT

PROMET-H2, Cost-effective PROton Exchange MEmbrane WaTer Electrolyser for Efficient and Sustainable Power-to-H2 Technology

The PROMET-H2 project aims to develop new technologies that will improve the processes of energy transmission to hydrogen, as well as its cost and storage. It is based on hydrogen as a solution for the storage of electricity produced with renewable energies, as these depend on highly variable climatic conditions. To encourage the use of these kind of energy sources, it is necessary to develop safe and competitive alternatives to electrochemical storage. Hydrogen, because of its high density, is a promising solution.

PROMET-H2 began on April 1, 2020 and is scheduled to end in April 2024.

2020

2020

2020

2020

2020

2020

2020

2020

2020

2021

2021

2021

2021

2021

2021

2021

2021

2021

2021

2021

2021

2022

2022

2022

2022

2022

2022

2022

2022

2022

2022

2022

2022

2023

2023

2023

2023

2023

2023

2023

2023

2023

2023

2023

2023

2024

2024

2024

What are the project’s objectives?

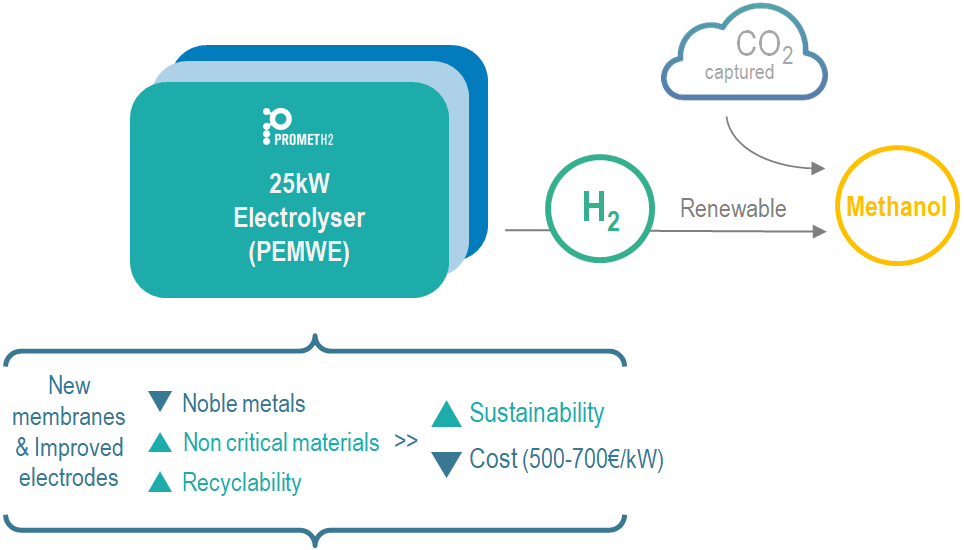

The main objective of the PROMET-H2 project is to develop a polymer technology electrolyser - one of the most suitable for coupling this process to the production of renewable methanol - reducing its current cost and making it more sustainable and reliable. This means developing its main elements, including the pressurized proton exchange membrane water electrolyser (PEMWE), at a lower capital cost than that achieved to date - between 500 and 700 euros per kilowatt (kW) - without compromising its performance and durability, and replacing noble metals with others that are more benign from an environmental and economic point of view. The heart of this electrolyser, the stack, based on hydraulic compression technology, will contain these new membranes and improved electrodes, increasing competitiveness in equipment manufacturing costs and reducing dependence on metals whose availability is not unlimited.

In addition to testing the components in the laboratory, the project consortium, in which 12 research centres and companies from six countries are participating, will construct a 25 kW electrolyser and the produced hydrogen will be used in a pilot plant for producing methanol from CO2. In addition, it will design material recycling strategies and assess that the new device can be scaled to higher powers to meet the demands of large industrial methanol producing plants, thereby closing the entire value chain, from the synthesis of new materials to the generation of the renewable fuel.